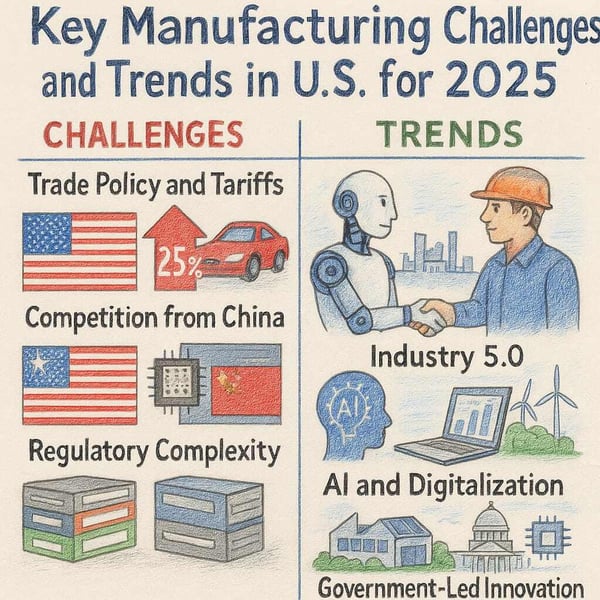

Key Manufacturing Challenges and Trends in the U.S. for 2025

The U.S. Manufacturing Landscape in 2025: Disruptions and Opportunities

In 2025, the U.S. manufacturing industry is navigating a shifting global landscape shaped by geopolitics, digital transformation, and sustainability. With new trade policies, increasing global competition, and evolving regulatory frameworks, staying ahead requires more than just operational efficiency—it demands strategic agility and innovation.

In this blog post, we explore the top manufacturing challenges and trends in the U.S. for 2025, and what they mean for forward-thinking manufacturers.

Major Challenges for U.S. Manufacturers in 2025

Trade Policy and Tariffs

The return of protectionist policies under President Trump—such as the 25% import tariff on vehicles starting April 2025—is impacting not only the automotive sector but also semiconductors and pharmaceuticals. These tariffs are driving up costs and prompting companies to reconsider their production footprints.

Competition from China

As the U.S. aims to reduce dependency on Chinese manufacturing, the government is pushing for domestic production of strategic technologies, especially in semiconductors. The Chips and Science Act, with $54 billion in funding, is a clear signal of this industrial pivot.

Regulatory Complexity

Manufacturers operating globally face increasing regulatory pressures, including the EU’s Corporate Sustainability Due Diligence Directive and the U.S. Buy America Act. These overlapping regulations complicate supply chain strategies and demand greater transparency.

Key Trends Shaping U.S. Manufacturing in 2025

Industry 5.0: Human-Machine Collaboration

Beyond traditional automation, Industry 5.0 brings a stronger focus on human-centric manufacturing, sustainability, and cybersecurity. Companies are seeking ways to harmonize advanced technology with skilled labor, enabling smarter, more resilient operations.

AI and Digitalization

The rise of AI in manufacturing continues—especially generative AI and agent-based automation. These tools are streamlining everything from production planning to internal meetings, driving process optimization and real-time decision-making.

Sustainability and ESG Demands

With rising pressure from stakeholders and regulators, companies are embedding Environmental, Social, and Governance (ESG) performance into their core operations. From green supply chains to energy-efficient production, sustainable innovation is no longer optional—it’s a competitive advantage.

Government-Led Innovation

The Chips and Science Act is a landmark $54 billion investment in the U.S. semiconductor industry, aimed at boosting competitiveness in key technology sectors. This underscores a broader trend: public-private collaboration to strengthen industrial capabilities.

What It All Means for Manufacturers

To thrive in this new era, manufacturers must:

-

Build flexible and resilient supply chains

-

Embrace smart automation and AI

-

Invest in sustainable practices

-

Navigate complex regulatory environments

-

Innovate at the intersection of technology and talent

Ready to Future-Proof Your Production?

OpiFlex helps manufacturers increase productivity and flexibility with patented automation solutions, mobile robots, and ultra-fast robot programming—perfect for high-mix, low-volume environments.

Explore our solutions or get in touch to learn how we can support your transformation.

Related articles

-

Robotization Mobile Robot System flexible robotics high-flexibility production Fast programming for robots Industrial robot applications

Robotization Mobile Robot System flexible robotics high-flexibility production Fast programming for robots Industrial robot applicationsHow One Small Manufacturer Runs 4000 Products Per Year—24/7—with a Flexible Robot

Discover how a small wood industry manufacturer automates 4000 products/year per machine—24/7—with no robot skills required. Flexibility is the key.

Read more -

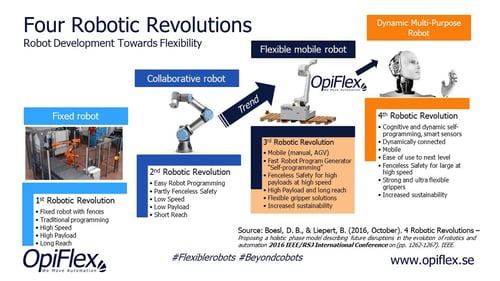

future-proof factories OpiFlex Dynamic Program Generator Industrial robot applications Flexible robotic applications Future of robotics in manufacturing

future-proof factories OpiFlex Dynamic Program Generator Industrial robot applications Flexible robotic applications Future of robotics in manufacturingThe Four Robotic Revolutions: How Flexibility Drives the Future of Manufacturing Automation

Discover the four robotic revolutions that have reshaped industrial automation. Explore how flexibility, from fixed robots to AI-driven cognitive machines, is transforming manufacturing.

Read more -

high-flexibility production Dynamic Program Generator Future of robotics in manufacturing

high-flexibility production Dynamic Program Generator Future of robotics in manufacturingThe Future of Manufacturing: How Flexible Automation is Reshaping Industry

Discover how flexible robotics are revolutionizing high-mix, low-volume production and sustainable manufacturing. Learn how mobile robots reduce downtime, scale production efficiently, and...

Read more

.png)