How One Small Manufacturer Runs 4000 Products Per Year—24/7—with a Flexible Robot

Imagine receiving a morning email from a customer, not with a question or complaint, but a photo of their robot running through the night—again. In fact, this small manufacturer in the wood industry frequently operates 24/7, thanks to a robot solution so flexible it handles 4,000 new product variants per machine per year, effortlessly.

This is the power of true flexibility in automation—where short runs, no-code setup, and mobile robots make what was once impossible now profitable.

How One Small Manufacturer Runs 24/7 With 4000 New Products a Year

The Challenge with Traditional Robots

Conventional robot solutions often fall short in high-mix, low-volume production environments:

-

Programming takes 8–10 hours or more per new product.

-

Skilled robot programmers are required.

-

Robots are fixed to one machine, limiting ROI.

-

Manual access to machines is blocked, reducing flexibility.

💡 The result? Robots sit idle, unable to justify their cost unless running long, repetitive series.

A New Approach to Flexibility and Productivity

One of our customers—a small subcontractor manufacturer in the wood industry—proves what's possible:

-

4000 new product variants/year—in each machine.

-

Short series in the morning, longer runs overnight and on weekends.

-

Mobile robot unit moved between machines as needed.

-

Uses Serialized One for zero-programming setup.

With this setup, they’ve unlocked:

-

📈 +52% productivity increase

-

⏱️ One-second robot programming

-

🧑🏭 Freed up 1.5 operators per shift

-

💰 Extra "free shifts" = profit directly to the bottom line

Why Mobility and No-Code Programming Matter

This customer can:

-

Start small series in the morning with zero setup time.

-

Let the robot run lights-out during evenings and weekends.

-

Move the robot to any machine—instantly adapting to demand.

⚠️ Without mobile, flexible robots, this would be impossible. Fixed robots with complex programming simply can’t keep up.

Benefits for the Real World of Manufacturing

This isn’t just a one-off success story. We have many customers achieving the same results.

Benefits include:

-

🧠 No need for robot programming knowledge

-

🛠️ Instant manual access to machines

-

📦 Scalable automation—even for small batches

-

💸 Faster ROI, more uptime, and reduced labor costs

Want to Run 24/7 Like This? Let’s Talk

If your robot stands still too often, it’s not paying off. Let’s change that.

Related articles

-

small series manufacturing fenceless safety Dynamic Program Generator Industrial robot applications Future of robotics in manufacturing

small series manufacturing fenceless safety Dynamic Program Generator Industrial robot applications Future of robotics in manufacturing10 Years of Disruption: How OpiFlex Redefined Flexible Robotics in Manufacturing

Discover how OpiFlex transformed robot automation with ultra-flexibility and smart programming—10 years after winning the EU's top innovation award.

Read more -

future-proof factories industrial robotics high product mix, low volumes flexible robotics high-flexibility production adaptable manufacturing

future-proof factories industrial robotics high product mix, low volumes flexible robotics high-flexibility production adaptable manufacturingKey Manufacturing Challenges and Trends in the U.S. for 2025

Discover the top U.S. manufacturing trends and challenges in 2025, from tariffs and AI to sustainability. Learn how companies can stay competitive.

Read more -

future-proof factories OpiFlex Dynamic Program Generator Industrial robot applications Flexible robotic applications Future of robotics in manufacturing

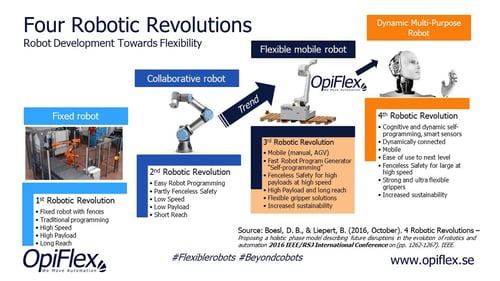

future-proof factories OpiFlex Dynamic Program Generator Industrial robot applications Flexible robotic applications Future of robotics in manufacturingThe Four Robotic Revolutions: How Flexibility Drives the Future of Manufacturing Automation

Discover the four robotic revolutions that have reshaped industrial automation. Explore how flexibility, from fixed robots to AI-driven cognitive machines, is transforming manufacturing.

Read more

.png)