How to automate high mix and low volume

The next generation of automation in industry has come to Sweden and the government is investing heavily in smart industry and the new automation. Among other things, it reduces costs and increases flexibility that allows high mix and low volume. Everything has already started to roll out in factories. Below we describe how to automate high mix and low volume. The guide is based on Edig’s article to increase knowledge in the industry.

The problem

Sweden is a role model in automation of larger production – But bad for small series production

Sweden has been a pioneer in terms of automating and streamlining the production process for larger production volumes. Within the group of small and medium-sized enterprises (SMEs) and small series production, the picture looks different. The companies mostly have a low degree of automation: 10 robots out of 10,000. Sweden has slipped behind the rest of the world in terms of automation, hence the government’s investment in automation and robotisation through, among other things, the “Robot Lift”. The government has also invested in “SWEDPROD Produce in Sweden” for the smart industry.

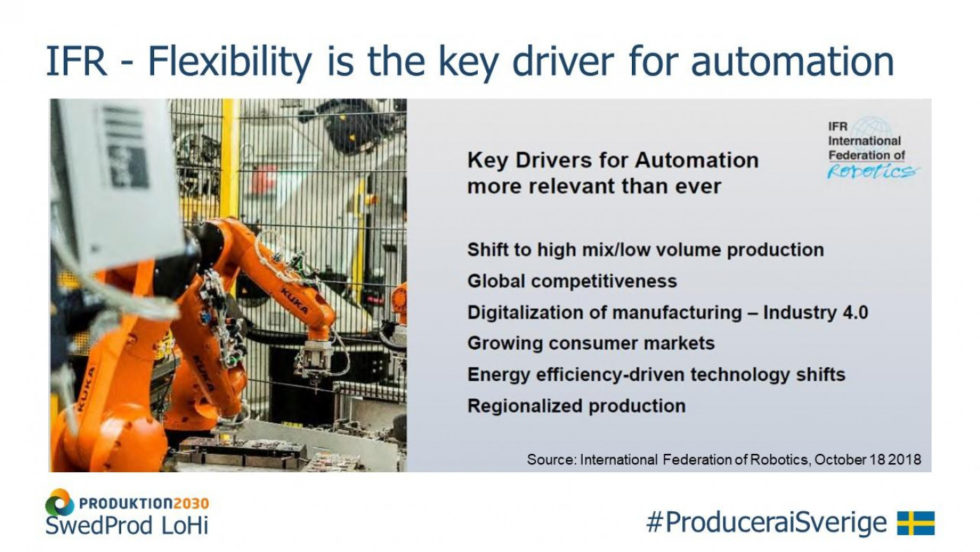

The megatrend high mix and low volume drives the need for flexibility

The trends “increased global competition” and “high mix and low volume” drive sharply increased automation in general and in particular flexible and future-proof automation. The background is that customers want greater freedom of choice of product configurations, shorter product lifetimes and higher competition. This is also something that the International Federation of Robotics presses, see picture below.

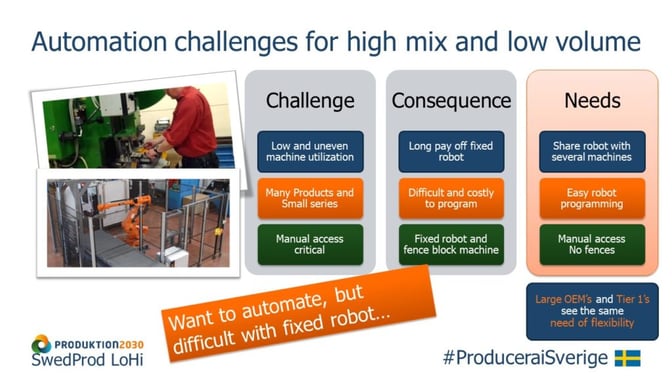

Why it is difficult to automate high mix and low volume.

Many companies want to automate small series production, but it is difficult for several reasons. The main reasons are:

- Robot solutions available in the industry have older technology and are made for high volume production

- Robot cells are specially built

- Robot cells are made to handle few products in many shifts over many years.

The solution – how to automate high mix and low volume

More flexible solutions are required to automate small series and high mix and low volume production!

In addition, you are required to meet the needs for flexibility that even large OEMs and Tier1 see in their future needs that go towards larger product mix.

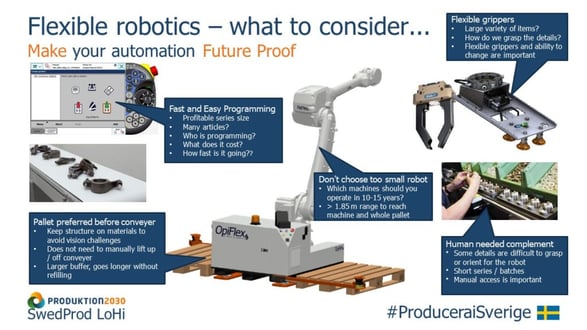

New solutions that help you automate high mix and low volume provide:

- fast and easy programming

- mobile robots – a robot for several machines

- safety solutions without fences even at high speeds and high loads

- flexible gripdon

- full manual access to the machine

The most important thing to think about for a future-proof automation solution

The most important thing for a better and more future-proof automation solution is flexible robotics. Read our study of the most important things for creating a flexible robot solution future-proof solution.

OEM and Tier1 groups are also driven by the need for greater flexibility

We see more and more large groups in, for example, the car industry, electronics industry, white goods, etc. that are driven by shorter series and higher mixes and where overall flexibility becomes more important to them. Many large OEMs have seen a challenge of increased automation as they “locked themselves in” with traditional fixed robot cells with fences as it is difficult to adapt these for new products or just to change the layout in the workshop.

Based on interviews and discussions with more than 30 global OEM and Tier1 groups in various industries such as automotive, electronics, appliances, consumer goods and furniture, we have arrived at the following guide with five common challenges for automation for OEM and Tier1

How the government invests in robotics

The government has invested SEK 100 million in the project “Produce in Sweden” which is also called SwedProd LoHi.

It is part of the government’s investment in smart industry through Production2030. The project is a research project to study how we can have a profitable, sustainable and competitive small series production in Sweden with flexible automation. The project is led by RISE in collaboration with Chalmers, Linneuniversitetet, IF Metall, Träcentrum, OpiFlex and many different companies in metal, wood, food and house construction. In the project, in addition to studies of needs and possibilities with flexible robot solutions, automation guidance and automation analysis tools for flexible automation of small series production have been developed, as well as a production economics model.

Edig’s article

Related articles

-

Robotization Mobile Robot System flexible robotics high-flexibility production Fast programming for robots Industrial robot applications

Robotization Mobile Robot System flexible robotics high-flexibility production Fast programming for robots Industrial robot applicationsHow One Small Manufacturer Runs 4000 Products Per Year—24/7—with a Flexible Robot

Discover how a small wood industry manufacturer automates 4000 products/year per machine—24/7—with no robot skills required. Flexibility is the key.

Read more -

Robotization Mobile Robot System automation Dynamic Program Generator Industrial robot applications Flexible robotic applications

Robotization Mobile Robot System automation Dynamic Program Generator Industrial robot applications Flexible robotic applicationsAdapting to Change: The Shift in Global Supply Chains and How Flexible Robotics Are Leading the Way

Discover how Jacob Wallenberg and Volvo's CEO are driving the shift towards nearshoring in manufacturing. Learn how flexible robotics and regional supply chains are reshaping production and helping...

Read more -

Mobile Robot System future-proof factories industrial robotics Dynamic Flow Optimization small series manufacturing high product mix, low volumes robot programming OpiFlex Dynamic Program Generator

Mobile Robot System future-proof factories industrial robotics Dynamic Flow Optimization small series manufacturing high product mix, low volumes robot programming OpiFlex Dynamic Program GeneratorIntroducing Dynamic Flow Optimization: Revolutionizing Robot Programming for Small Series Manufacturing

Discover how OpiFlex's Dynamic Flow Optimization revolutionizes robot programming for small series manufacturing, making it faster and simpler than ever before.

Read more

.png)